Essential Tips for Proper TIG Filler Rod Storage to Prevent Rust and Contamination

- extremetig

- Oct 21, 2025

- 3 min read

TIG welding demands precision, and that precision begins with quality materials, particularly the filler rods. However, even the finest filler rods can deteriorate if not stored correctly. If you want to perform high-quality welds, it’s crucial to understand how to properly store your TIG filler rods to prevent issues like rust and contamination. In this post, we’ll look closely at signs of improper storage, offer practical storage solutions, and highlight how TIGSleeve™ can enhance your welding experience.

Signs Your TIG Filler Rods Need Better Storage

Rust Formation

Rust is a clear indicator that your TIG filler rods are not stored correctly. If rods are exposed to moisture — even from workshop humidity above 50% — the risk of rust increases significantly. A few rust spots can reduce weld quality because contaminants in the weld pool may weaken joint strength. Research shows that using rusty materials can lead to weld failures up to 30% of the time.

Bent Rods

Bent rods are another signal that storage methods need improvement. Filler rods must stay straight for proper feeding into the torch. Improper stacking or leaving rods unprotected compromises structural integrity. Even minor feeding issues can waste time, cause frustration, and affect weld quality.

Contamination

Contamination is a serious threat to TIG welding quality. Dust, oil, and other pollutants can cling to filler rods if they aren’t sealed during storage. These impurities transfer into the weld pool, causing porosity and weakened joints. In uncontrolled environments, contamination-related weld defects can reach 15%, leading to rework and wasted consumables.

Solutions for Proper Storage

Use a Dry Environment

To combat rust, keep rods in a dry environment. If humidity is a problem, use a dehumidifier to bring levels down by up to 60%. Store rods in airtight containers with moisture protection. O-ring sealed sleeves are the best choice to block humidity and dust.

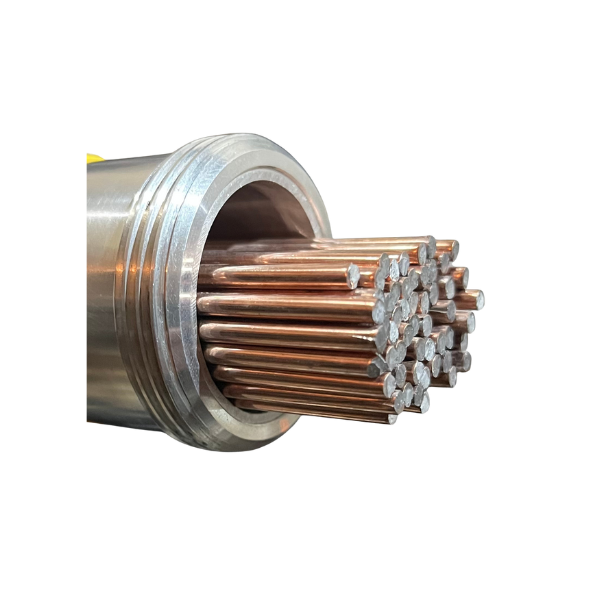

Invest in Proper Storage Solutions

Dedicated TIG rod sleeves are built to prevent bending, contamination, and alloy mix-ups. TIGSleeve™ is designed with welders in mind — precision-machined from durable 6061 aluminum, featuring an airtight O-ring seal, and anodized for long-lasting protection. Its rugged design ensures rods stay straight, dry, and job-ready.

Regular Inspections

Set a schedule to inspect filler rods weekly or monthly for early signs of rust, bends, or contamination. Addressing problems quickly prevents wasted rods and keeps your welding standards high. Replace or clean rods before they compromise weld quality.

Why Choose TIGSleeve™

Quality Materials

TIGSleeve™ is handcrafted from grade 6061 aluminum with a corrosion-resistant anodized finish. Its airtight O-ring seal and precision screw cap keep rods free from rust, dust, and damage.

Color-Coded Options

Each TIGSleeve™ is available in multiple colors, allowing welders to easily organize alloys and sizes. This reduces mistakes, saves time, and improves workflow efficiency.

Expert Support

In addition to premium products, TIGSleeve™ provides expert guidance on best practices for filler rod storage. Our team understands the challenges welders face and ensures you get the maximum benefit from your storage solution.

Final Thoughts

Proper TIG filler rod storage prevents problems like rust, bending, and contamination. By recognizing the warning signs and applying the right solutions, you can improve the quality and consistency of your welds. TIGSleeve™ delivers airtight, durable, and professional-grade rod protection so your filler materials are always ready for the job. Remember — great welds start with well-preserved rods.

Questions? See our FAQ

Comments