How to Store TIG Welding Rods Properly: A TIG Rod Storage Guide

- extremetig

- Sep 24, 2025

- 2 min read

TIG welding demands precision, and the condition of your filler rods can make or break a weld. Too often, welders lose rod quality to rust, moisture, or contamination before even striking an arc. In this guide, we’ll cover why proper TIG rod storage matters, common mistakes to avoid, and the best solutions for keeping rods clean, dry, and job-ready.

Why TIG Rod Storage Matters

TIG filler rods are sensitive to their environment. When exposed to humidity or dust, even briefly, rods can corrode or collect contaminants. This leads to porosity, uneven puddle formation, and weld defects that may not show up until inspection. Keeping your rods in proper condition ensures consistency, saves money, and reduces frustration on the job.

Common Mistakes Welders Make with Rod Storage

Leaving rods in original packaging

Many rods come in cardboard or thin plastic sleeves that aren’t airtight. These containers quickly absorb moisture, leaving rods vulnerable to corrosion.

Mixing alloys

Throwing different alloys in the same case wastes time and risks using the wrong filler during critical welds. Color coding or labeling is essential for efficiency.

Improvised storage solutions

PVC tubes and DIY containers are cheap but rarely airtight. They can keep rods together, but they won’t protect against humidity or long-term damage.

Best Practices for TIG Rod Storage

Keep rods airtight

Always use storage solutions with a secure seal to prevent moisture from entering. An O-ring or gasket ensures long-term protection, even in humid environments.

Organize by alloy

Color-coded sleeves or clear labeling save time and prevent costly mistakes when switching between stainless, carbon, aluminum, or Inconel.

Choose durable materials

Thin plastic cases can crack or warp. A strong aluminum tube provides durability for shop and field work, protecting rods from bending and contamination.

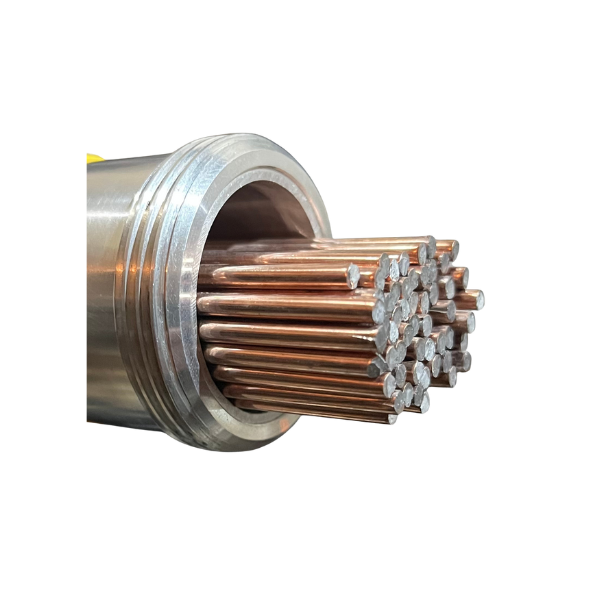

Why Welders Choose TIGSleeve™

Not all TIG rod cases are built the same. TIGSleeve™ is handcrafted from aerospace-grade 6061 aluminum with a clear anodized finish. Each sleeve is airtight, color-coded, and built to last. A precision screw cap with O-ring seal protects rods from moisture, while a detachable strap makes transport easy. With five color options, TIGSleeve™ keeps rods organized and secure whether you’re in the shop or on the job site.

Final Thoughts

Proper TIG rod storage isn’t just about convenience — it’s about weld quality. By keeping filler rods airtight, organized, and protected, welders avoid costly defects and wasted materials. If you’re ready to upgrade your setup, explore the full line of TIGSleeve™ rod storage tubes and see the difference for yourself.

Comments